Elemental technologies

Mechatronics, Machine vision and Ultrasonic technology to support your production.

One of the reasons for choosing KAIJO as a production partner is our wide range of 'Elemental

technologies'. We have a long history of R&D and hope that these elemental technologies will

support the next generation of industry.

Mechatronics and Machine vision technology

KAIJO uses the mechatronics and machine vision technology know-how it has acquired through the

development of semiconductor equipment to propose in-line systems that are optimised for

customer production.

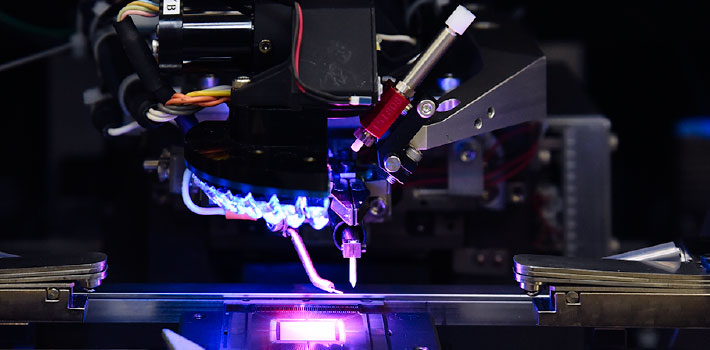

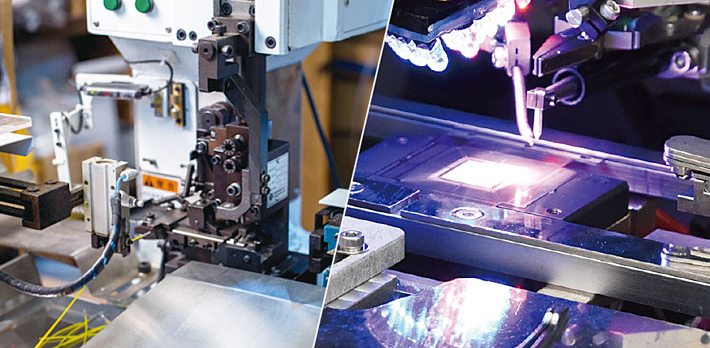

< Mechatronics >

Technology for automatic production lines with high-speed, high-precision control.It significantly

reduces the time required for assembly, improves productivity and stabilises quality.

< Machine vision >

High-precision positioning technology based on ultra-high-speed image recognition.Positioning of

even small workpieces in less than 0.1s (1/10th of a second) is possible.High-precision fail

judgement is also possible using image recognition.

Bonding technology for dissimilar materials

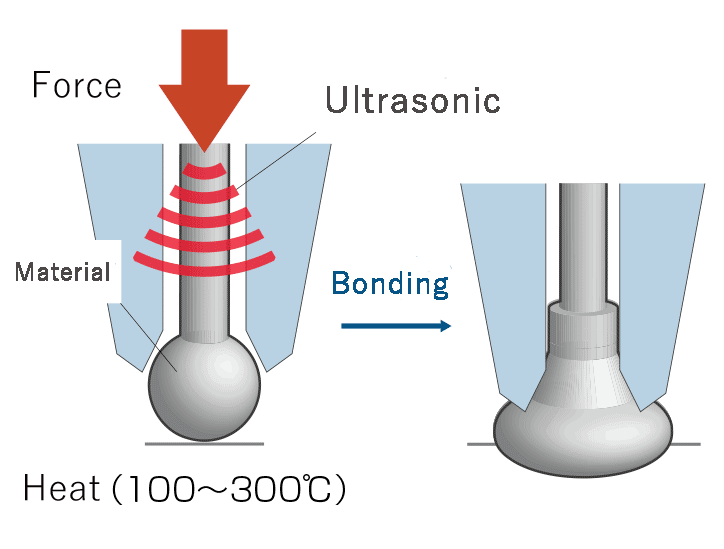

The ultrasonic bonding technology that KAIJO has acquired in the development of semiconductor

machines is applied to a wide range of applications. We are expanding our research into materials

other than metal bonding.

Ultrasonic wire bonders are used in the manufacture of semiconductor devices in the process of joining IC chip electrodes and leadframes with metal wires. Ultrasonic can be used to bond objects without

melting them. This technology is also used to bond between different materials.

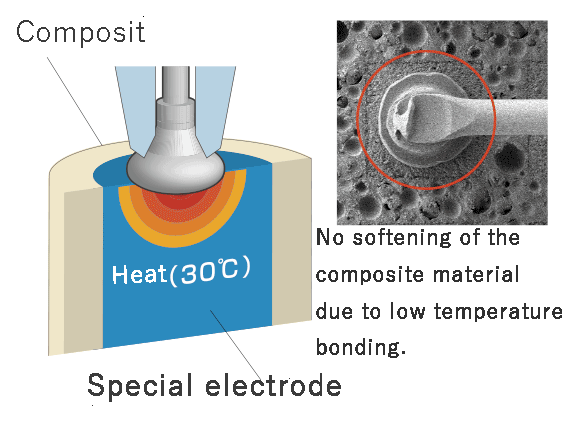

Solid-state bonding

Methods of bonding metals without melting.

Low temperature bonding is possible even with non-heat resistant materials.

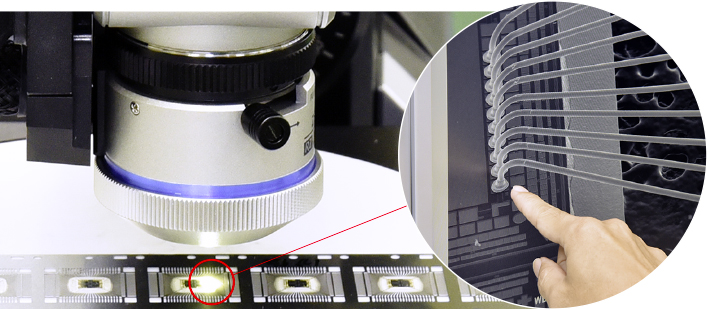

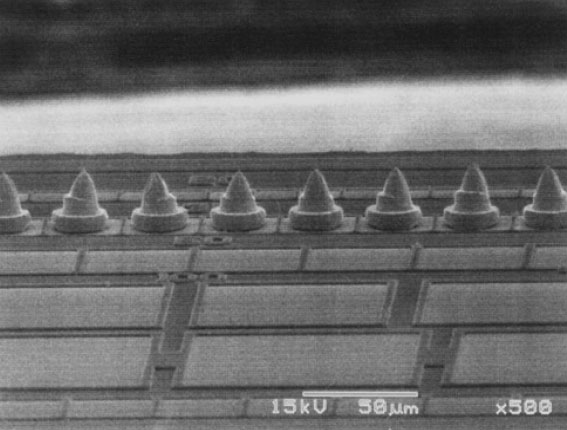

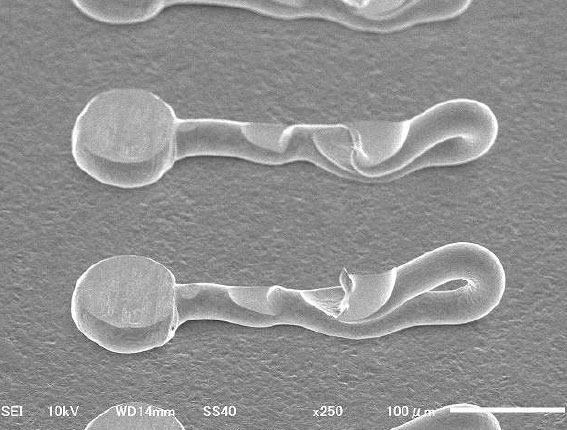

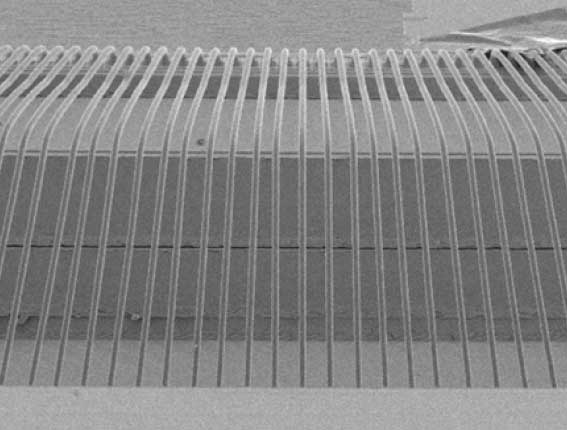

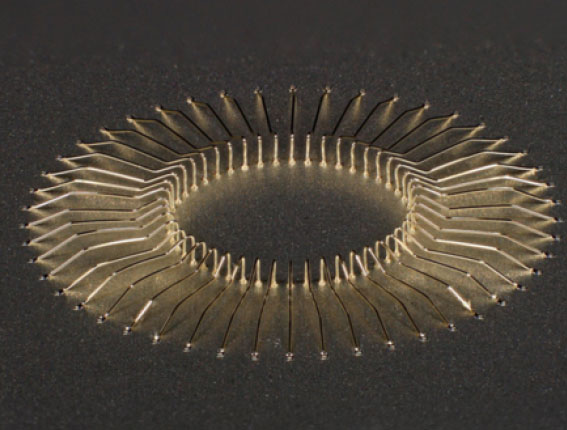

Bonding technology for ultra-fine wire

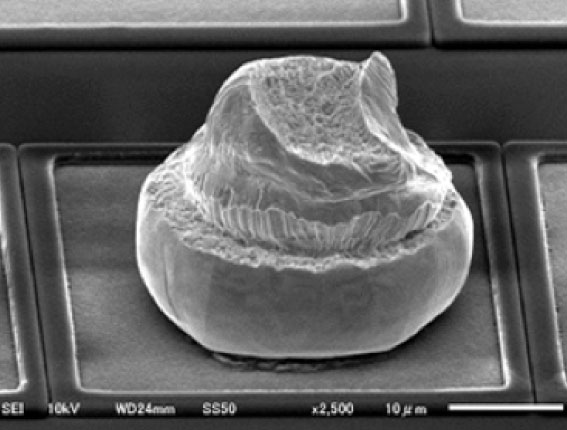

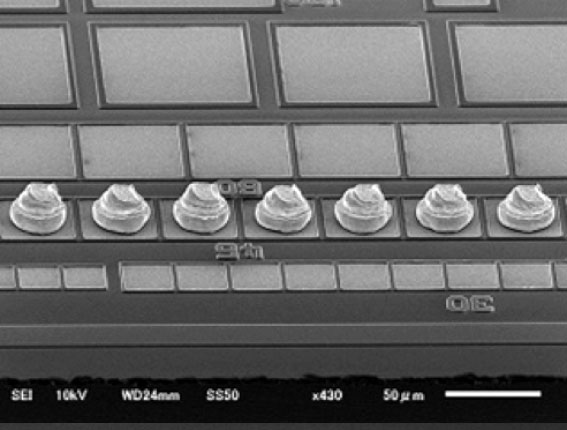

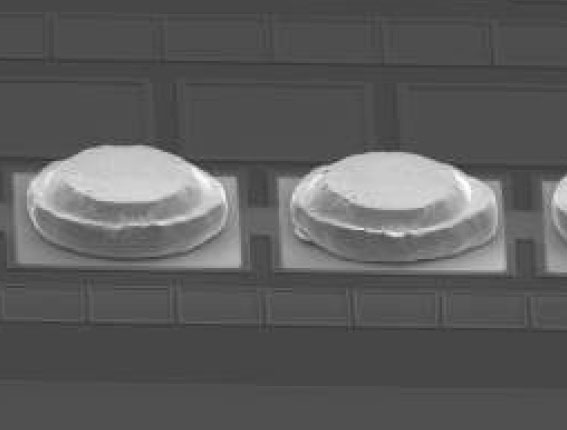

The connecting electrodes formed on semiconductor chips or wiring leads are called bumps, which

require bonding technology using, for example, 15 µm gold wire at a pitch of 35 µm. The shape of the

bump tip can be processed and this know-how can be applied in other fields.

Ultra-fine bump bonding

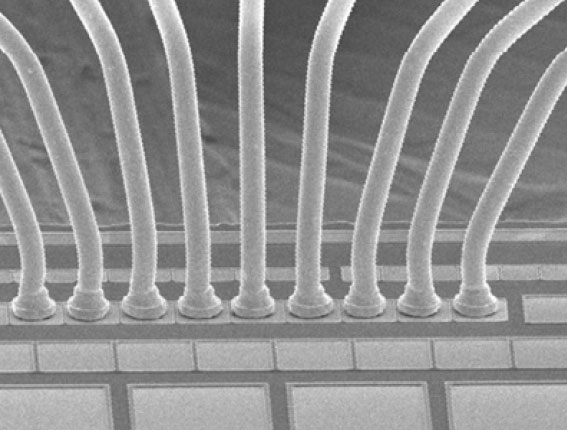

Ultra-fine wire bonding

This is an example of fine pitch bonding using ultra-fine wire.

PDA pitch 30μm

Enlarged view (wireφ 12.5µm)

Whole image

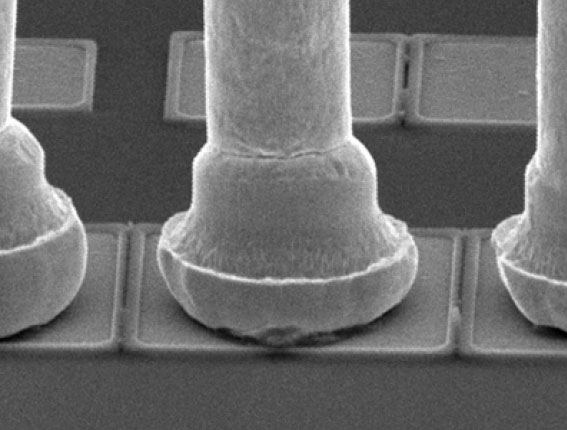

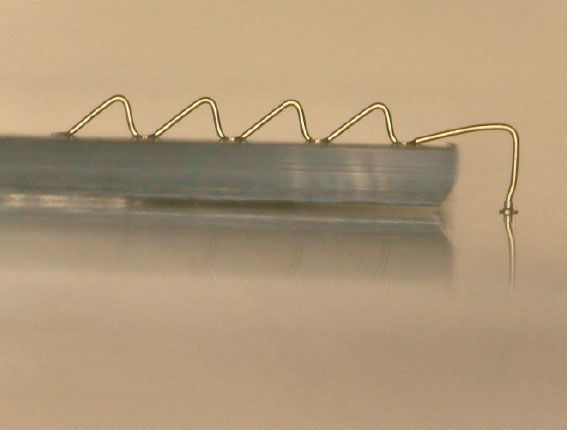

Applied to electrode

An example of electrode joining with platinum. Size can be up to the equivalent of 4 times the wire diameter. The sphere size at the tip can be adjusted by setting.

e.g. 1

e.g. 2

e.g. 3

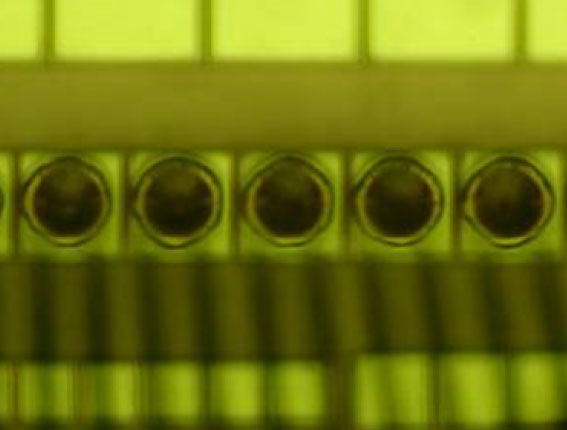

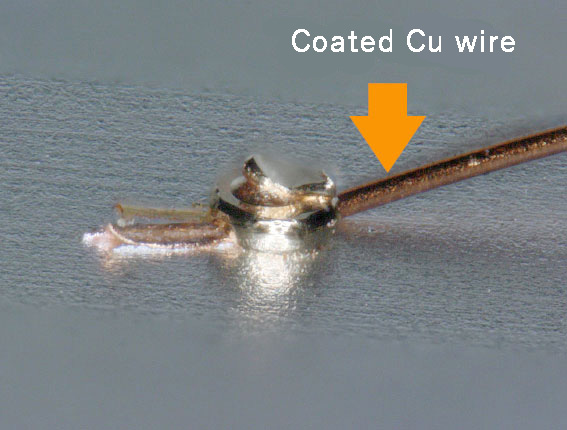

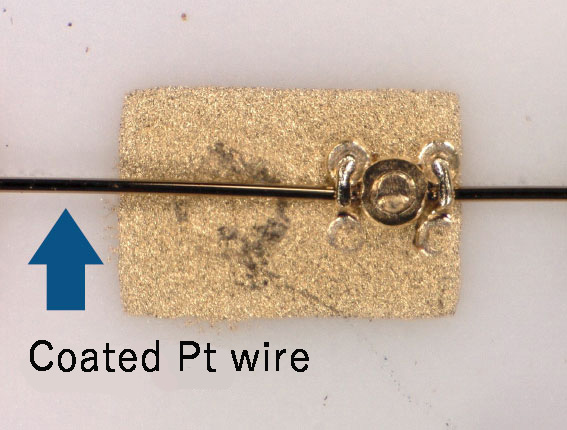

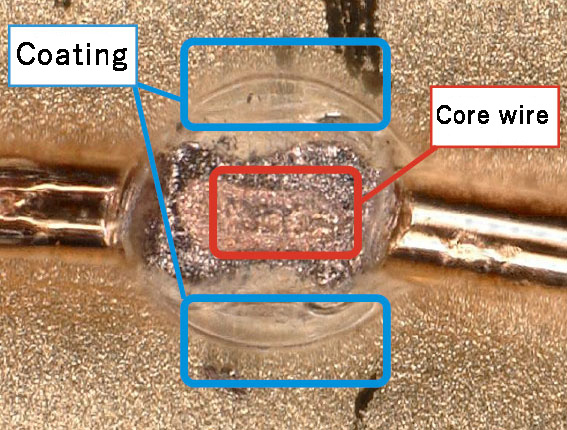

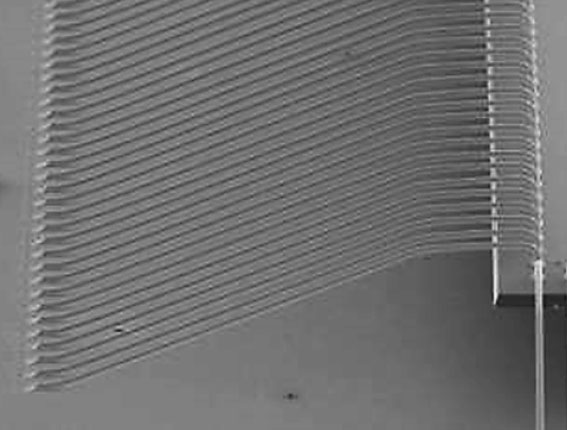

Bonding technology for insulated coated wires

KAIJO has bonding technology with polyurethane coatings. We have expertise in micro-bonding and have applied for a process patent for the technology to remove the coating by ultrasonic. This reduces the amount of soldering work that used to be carried out manually, saving manpower and realising automation.

Enlarged top view

Flexible wiring technology

KAIJO has a wide variety of highly flexible wiring technologies developed in electrode-to-electrode connections. For example, it is possible to form 'chain loops' with ultra-fine wires.

Staggered wiring

Large gap

Overhang

Chain loop

Wiring flexibility

High accurate repeatability

Even if you are just at the idea stage,Please do not hesitate to contact us.

- Contact InformationInquiries about products

- Please contact us for technical inquiries and technical information from here.