What is Ultrasonic welding?

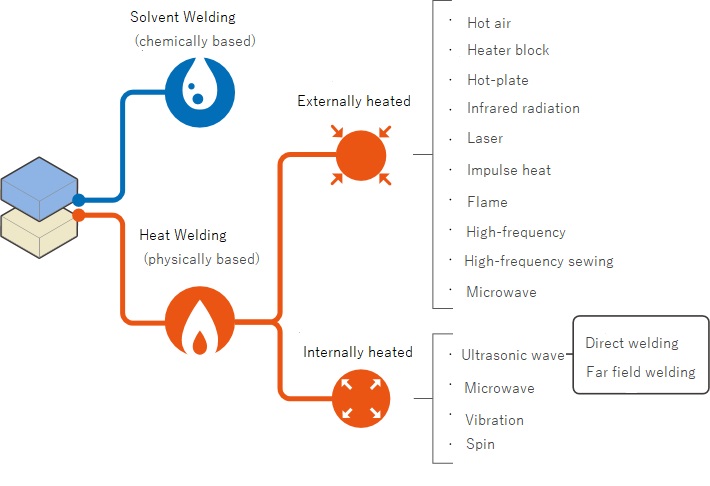

What are the available methods for welding plastic?

There are two primary methods for welding plastics

One is to use a "solvent" such as an adhesive. The other is to use "heat". The former is a "chemical" approach while the latter is a "physical" approach. Furthermore, heat welding is classified into two types.

One is “external heating”, and the other is “internal heating". Most of the heat welding methods, such as hot air welding, electric welding, infrared welding and laser welding are external heating methods. On the other hand, ultrasonic welding, vibration welding, and spin welding utilize internally generated frictional heat.

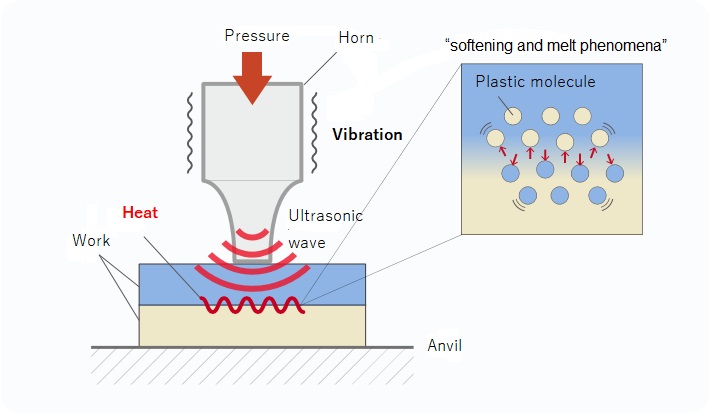

Principles of ultrasonic welding (mechanism)

The mechanism of ultrasonic welding is very simple

The horn delivers internal ultrasonic vibrations into the plastic material. Welding heat is produced from these vibrations.

The welding is done by heat that liquifies the connected area of the plastic work pieces causing the entanglement of the plastic’s polymer chains to form the primary chemical bond. In other words, the ultrasonic vibration heats at the inner parts of plastic which causes the “softening and melt phenomena”. As a result, the work pieces are bonded.

The same mechanism is used for metal welding in which internal ultrasonic vibrations are delivered to the metal work piece. The ultrasonic vibrations create friction on the bonding surface of the metals. The friction also destroys the surface oxide layer, to promote welding

Types of Ultrasonic welding

There are two types of ultrasonic welding. One is direct welding and continuous ultrasonic welding caused by “stretching vibration.”

The other is transmission welding using “plastic deformation” under surface.

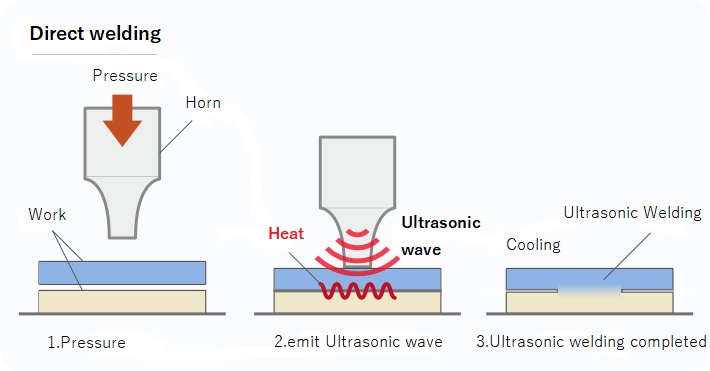

Direct welding

Two plastic objects are held together in a fixture, one of the objects is in contact with an ultrasonic horn. When the horn is activated, an ultrasonic wave travels through the contact object to the interface of the two work pieces. The ultrasonic wave vibrates the work pieces against each other to create frictional heat. The plastic parts melt together and then vibration is stopped. The plastic cools to complete the weld.

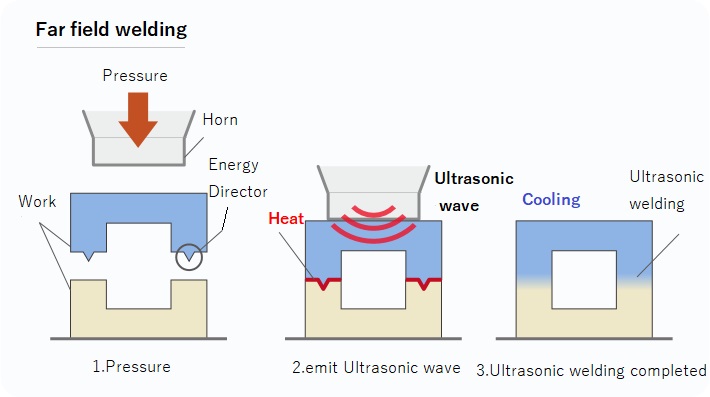

Far field welding

On the other hand, Far Field welding is appliable to hard-plastic only.

It adjusts the static pressure transmitted from the horn and uses an extremely small gap between the welding surfaces of both plastic workpieces then delivers ultrasonic vibrations from the horn through the plastics.

This vibration wave is not distorted inside the plastic, but transmitted through the upper-side plastic as velocity and crate a collision with the lower-side plastic piece. The heat that is released in this collision completes the welding process.

Welding is not only possible when molded parts are placed in near proximity to the horn, it’s also possible when there is a considerable distance between the horn and the molded parts. Even relatively thick parts, such as molded products are easily welded without heating unnecessary areas. The results are a strong, typically scratch-free weld.”

Advantages of ultrasonic welding

- Applicable to almost all types of thermoplastics

- Multi-point simultaneous welding and consecutive welding possible

- Possible to weld even if the surface is slightly dirty

- Possible to shorten welding time significantly

- No consumables, low operation cost

- “Energy saving” Eco friendly, since electricity is supplied only during welding process

- Welding device is small in size and reasonable in price

- Contact InformationInquiries about products

- Please contact us for technical inquiries and technical information from here.